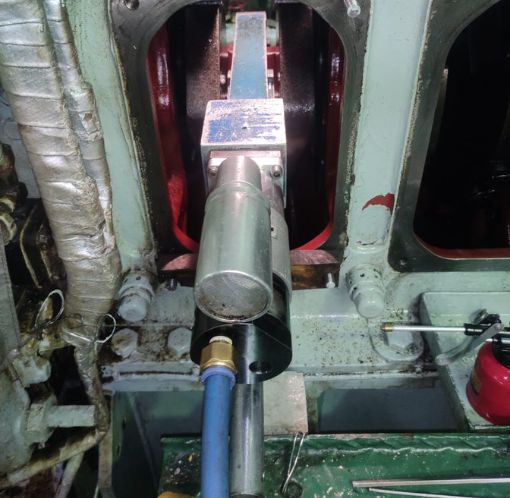

COMPRESSOR SHAFT GRINDING

MPA Power Project services all compressor shaft grinding needs! Many locations depend on compressors, keeping them running is essential. Our compressor shaft restoration services include land, offshore, and ships around the world. MPA Power Project believes that a skilled workforce is a powerful workforce. Our knowledgeable and trained field machinists are supervised by experts. Each and every technician and manager has trained, gained experience, and worked with the best technical experts available from the top manufacturers of engines, leading institutions, and certification authorities. We understand engine types and design. We have a number of different engine-specific portable machining and grinding tools. With dedicated rotor and compressor shaft grinding tools, we can meet your needs quickly. It is costly when any business is being serviced. MPA Power Project has eliminated that with the use of state-of-the-art compressed air technology. This new technology reduces engine downtime with quick restarts. Count on MPA Power Project to decrease compressor shafts. Find out firsthand how a free consultation can make a difference based on great service and knowledge!

Quality Compressor & Rotor Shaft Grinding Onsite Process with MPA Power

Your business runs perfectly with the compressor. In many professions, it is a well-kept secret. Powerful engines can break down. Introducing MPA Power. They offer the best on-site compressor shaft and rotor shaft grinding. Unfortunately, a broken compressor can halt work for you instantly. MPA Power can assist you on land, offshore, or any ship at any time. Fast, reliable service is our mission across all regions. Talent powers the success of our team. In addition to being talented, our field machinists are precise in everything they do. Talent is insufficient on its own. All of our managers and technicians have worked alongside leading technical experts from engine manufacturers, schools, and certification bodies. This valuable experience has taught me the different types of engines and on-site compressor and Rotor Shaft Grinding Onsite. A broken compressor must not hinder your work. Contact MPA Power now to receive unrivaled spot grinding services from experts.

Best Business Solutions with Compressor Shaft Grinding

Fantastic Advantages with Rotor Shaft Grinding Onsite

Finest Rotor & Compressor Shaft Grinding Repairs

MPA Power offers excellent rotor and compressor shaft grinding damage repairs for equipment performance. Our intensive process begins with a pre-inspection. The condition of the shaft will be a detailed account. The in-situ dye penetrant and magnetic particle testing of hardness and fractures make measuring an easy task. The health of the shaft next undergoes tests for displacement and trueness. Our team sources the best solution according to the pre-inspection report and level of damage. To reach OEM taper and ovality specifications (to within 0.02mm for roundness and alignment), the damaged fillet radius portions may require careful regrounding or the crankshaft may need grinding on the field. We use world-class methods to prepare a surface polish of better than 0.30 µm Ra. This optimizes rotor or compressor shaft performance and lifespan.

Frequently Asked Question ?

Contact Us !

- 155, Sector-47, Gurgaon-122018 Haryana (INDIA)

- +91 9811282433, +91 9999500177

- info@mpapowerproject.in

- 0124-2217971