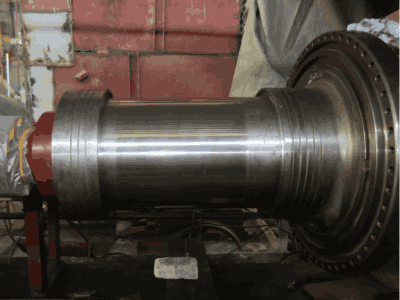

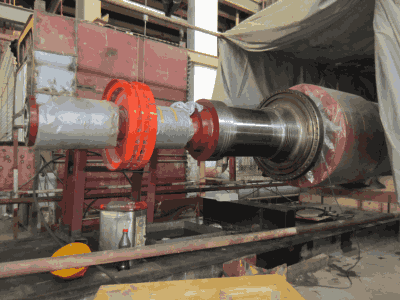

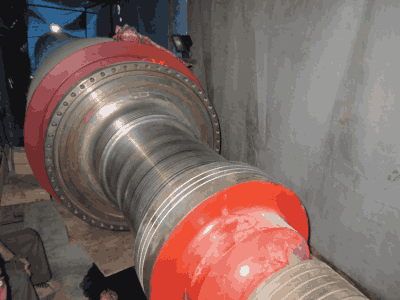

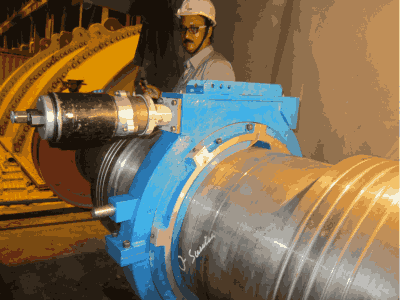

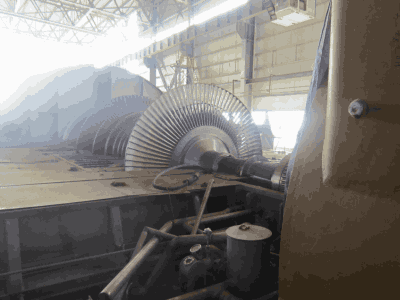

MPAPPPL has the latest breed of mechanism operated by pneumatic compressed air. We have in-house facility for crack detection, hardness check, trueness checking of shaft and white metalizing/rebabbitting of bearing.

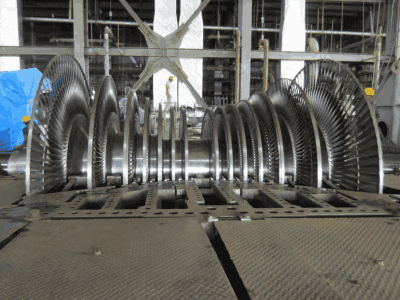

We offer services for turbine shaft, rotor shaft and alternator shaft.