For a marine vessel to operate efficiently on the sea, it is essential to have different kinds of engines used to maintain different types of engines. There mainly exist two kinds of these: the main and the auxiliary, with the former responsible for propelling the vessel while the latter also plays a very important support role in that it powers important systems such as electricity and hydraulic among others. Very essential to this end, it’s therefore important to have regular repairs and overhauls of engines done for the constant operation of these systems, for safety, and even for optimizing performance. Failure to keep these engines in good condition leads to cost breakdowns, unsafe conditions, and operational inefficiency. This is what makes Main and auxiliary engine repairs so special.

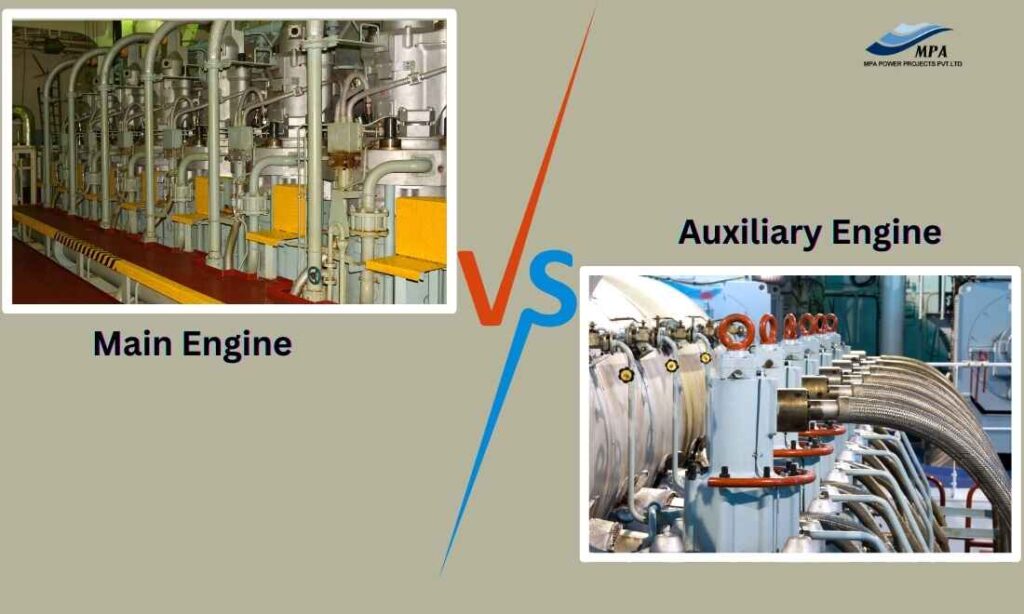

Main Engines and Auxiliary Engines

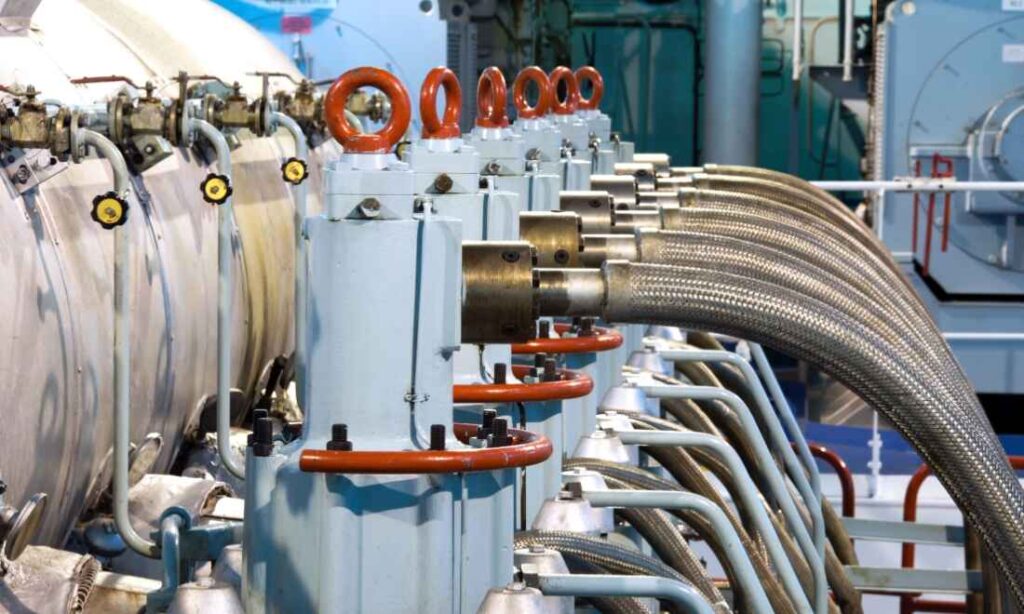

Main engines are the powerhouse of a ship and what thrusts the vessel through the water. They are large, robust machines geared with a great amount of power for moving the ship.

Auxiliary engines will be smaller in size while powering the electrical, hydraulic, and other auxiliary systems of the ship. Though not involved in propulsion, their service is vital to the whole operation of the ship.

Both the engines require regular servicing and overhauling to prevent failures and also increase their usage period. Proper maintenance of these engines plays a very important role in safety for marine as well as ensures complete functionality of the ships in their voyage.

Understanding Main Engine Repairs

What is a Main Engine?

A marine vessel contains a main engine which acts to convert fuel into mechanical energy to make the propeller of the ship operational. This component cannot move the vessel independently. The main engines differ from diesel engines to gas turbines based on the size and type of the vessel.

Role and Function in Maritime Propulsion

The main engine generates the force based on the combustion of fuel passed through a succession of mechanical components to transmit the power to the propeller shaft, pushing the ship forward. It is among the critical parts responsible for the movement of propelling the vessel forward. They usually endure extreme mechanical stress and strain that causes them to break down with time.

Common Issues in Main Engines

Main engines have several problems due to the constant operation in the hostile marine environment. Among the problems include the following:

Wear and Tear: Due to steady use, mechanical parts tend to disintegrate.

Corrosion: Moisture in saltwater and the high adverse environmental conditions tend to cause corrosion, which rusts the body of the engine and weakens it.

Fuel System Issues: Adulteration of fuel or clogged injectors may compromise the performance or effectiveness of the system.

Each one of these issues causes inefficient operation of the engine and, in extreme cases, total breakdown.

Steps Involved in Main Engine Repair

In main engine repair, this process involves highly extensive and complicated details that should be taken into consideration. Some of the essential steps involved are:

Diagnosis: Diagnosis in identifying problems by indications in the performance of the engine and analysis through visual inspection.

Parts Replacement: Damaged or worn parts such as pistons, cylinders, or injectors are replaced.

In-Situ Repairs: Most repairs within an engine take place without full disassembly, for instance, welding, or machining, parts in-situ.

Testing: Testing of such an engine after repair so that the engine is thoroughly tested in terms of its working condition and should be safe to use.

The Importance of Timely Repairs

The vessel may stop a major breakdown which may leave the vessel grounded if addressable issues are attended to as soon as they arise. This improved efficiency of the engine gives way to increase operational life, and hence, saving against expensive emergency repairs and thereby efficient idle time.

Main Engine Overhaul

An engine overhaul refers to the full disassembly and cleaning of an engine, inspection, and even parts replacement. Works are usually done at predefined regular periods or when the engines have worn out significantly with noticeable defects.

When an Overhaul is Required: Overhauls are typically required when regular repairs no longer prove sufficient to maintain performance, usually after some significant number of operating hours or after significant problems in performance.

Auxiliary Engine Repairs

Role of Auxiliary Engines in Ships

Spare engines provide backup power to cater for different power requirements, such as electrical power, hydraulic operations, as well as the air condition systems of the ship. The extra engines provide emergency power so that the secondary systems of the ship continue operating when the main engine has been shut down or is running on low power.

Common Auxiliary Engine Problems

Spare engines, like any other type of engine, have their set of problems. Some of these include:

Oil Leaks: With time, the seals and gaskets deteriorate, causing oil leaks.

Vibration Problem: At times, some parts of the engine get damaged due to extreme vibrations; this reduces efficiency.

Overheating: Failure or undercooling of the cooling system leads to the overheating of the engine, which damages the same.

Repair Process for Auxiliary Engines

Repairing auxiliary engines involves:

Maintenance by scheduling: This is done by checking and replacing parts so that the engine may work efficiently.

Emergency Overhauls: In cases of unexpected breakdowns of main engines, emergency overhauling is carried out to restore the function as quickly as possible.

Overhauling Auxiliary Engines

Aided by the fact that auxiliary engines, like the main engine, are under continuous overhaul for maintaining efficiency and functionality, routine overhauls ensure that such auxiliary engines do not fail to support the ship’s operations at odd moments.

Key Differences: Main vs. Auxiliary Engine Repairs

Scope of Repairs

Main engine overhauls are generally much more complex due to the size and importance of this critical piece of machinery and, therefore, the increased mechanical load of the engine.

Auxiliary engine overhauls, though still so important, are usually less complex systems and, therefore, done much faster.

Cost Implications

Main engine repair is costly because it is a big and complicated engine on which the ship relies very much for its propulsion. Then, auxiliary engine repair can be less expensive but similar in their complexity, too. For all these reasons, regular maintenance has to be scheduled.

Maintenance Schedules

A good average production engine needs a longer cycle of inspection before it comes in for overhaul because of the high build quality, but when it does come in for an overhaul, it is intense. Auxiliary engines need more frequent routine overhauls because of their tasks supporting main-engine operations; however, the tasks themselves are often less intense.

Best Practices for Engine Repair and Overhaul

Importance of Regular Inspections

Regular checks are done to trace possible faults in good time to prevent breakdowns and ensure the main and auxiliary engines are left in good working conditions.

Using Certified Technicians

Qualified marine engineers employed to carry out the repair work will ensure quality job. The technicians are both skillful and experienced in all the intricate works of an engine repair and overhaul.

Genuine Spare Parts

Using OEM parts will then guarantee compatibility, good performance, and long durability for repairs. Originally manufactured parts were designed to satisfy or meet the demands of the engine and, thus, minimize the chances of failures in the future.

Predictive Maintenance Tools

Future-proof technology, including predictive maintenance software, allows operators to monitor real-time health of the engine and predict possible failures with a means to plan maintenance prior to the failure.

Benefits of Professional Engine Repair Services

Minimized Downtime

Professional repair services tend to solve problems quickly and effectively, hence reducing the time a vessel spends inoperative. This implies that the vessel is put back into service and utilized faster, resulting in loss mitigation through downtime.

Extended Engine Life

Proper maintenance and timely Repair and overhaul of engines main and auxiliary increase their life with service, thus preventing the replacement of expensive prime movers and smooth engine operation in the long run.

Cost Savings

Preventive maintenance and early repairs avoid expensive emergency repairs. Early concern and regular actions can help save enormous amounts throughout the lifetime of an engine.

Conclusion

In summary, repairs are fundamental to the proper operation of ocean-going vessels. Main and auxiliary engines, whether propelling the vessel or powering vital systems, should not be overlooked. Regular maintenance and timely repairs are essential to prevent losses in efficiency, reliability, and safety. Overhauls must be performed to avoid frequent breakdowns and minimize repair costs, all while enhancing marine safety through the diligent upkeep of main and auxiliary engine repairs.

No Comments